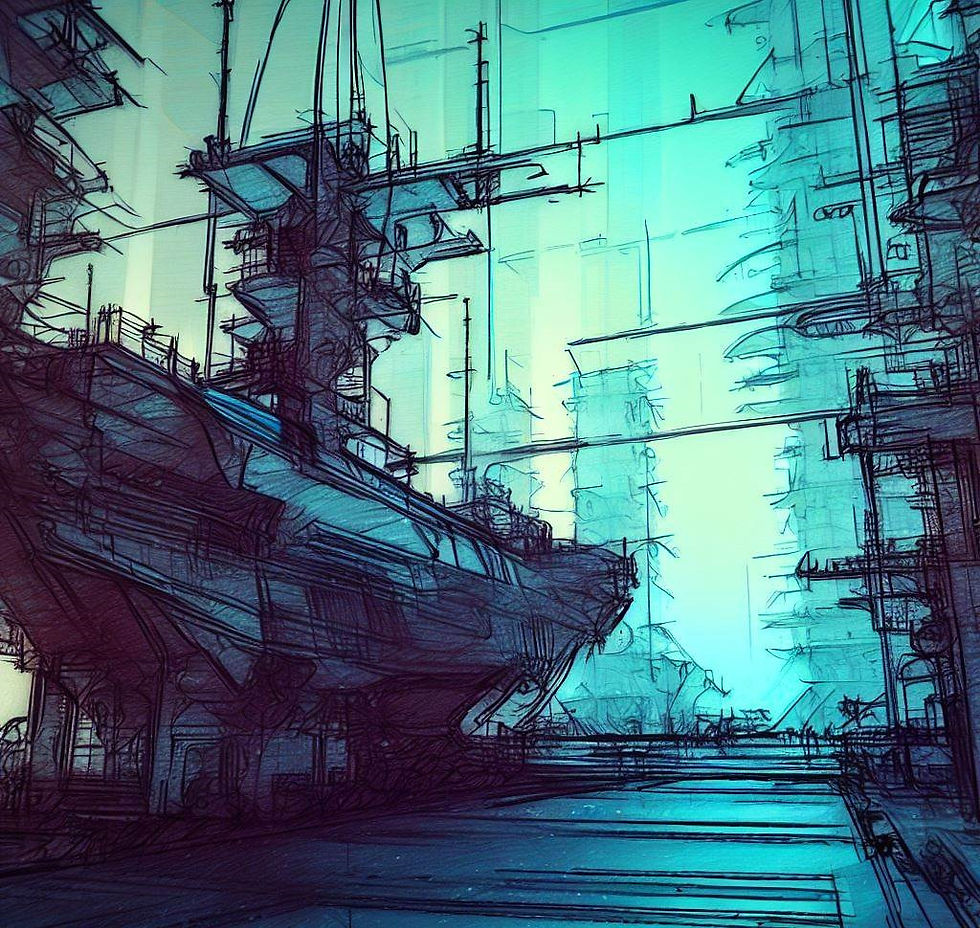

How AI and Analytics are changing Shipbuilding Industry

- Insivue

- Jun 12, 2023

- 4 min read

Artificial intelligence (AI) and analytics are rapidly changing the shipbuilding and maritime construction industry. By harnessing the power of advanced algorithms, machine learning, and data analysis, these technologies can enhance productivity, efficiency, safety, and decision-making processes. In this article, we will explore how AI and analytics can foster the growth of the shipbuilding and maritime construction business.

Design and Engineering

One area where AI and analytics can have a significant impact is in the design and engineering phase of shipbuilding. Traditionally, naval architects and engineers relied on manual calculations and simulations to develop ship designs. However, AI can automate and optimize these processes, enabling faster and more accurate design iterations. By analyzing vast amounts of historical data on ship performance, weather conditions, and operational parameters, AI algorithms can generate optimized designs that meet specific performance requirements while minimizing fuel consumption, emissions, and construction costs.

Predictive Operational Control

Moreover, AI-powered simulation tools can predict how a ship will behave under different operating conditions, helping identify potential structural weaknesses or areas prone to corrosion. This predictive capability enables shipbuilders to make informed decisions about materials, construction techniques, and maintenance schedules, resulting in more durable and reliable vessels.

In the construction phase, AI and analytics can streamline operations and improve project management. AI algorithms can analyze project schedules, resource allocation, and logistics data to optimize construction workflows, reducing delays and cost overruns. By integrating real-time sensor data from construction sites, AI systems can identify potential safety hazards and alert workers, mitigating the risk of accidents and injuries.

AI-powered robotics and automation can also revolutionize shipbuilding processes. From automated welding and painting robots to unmanned aerial vehicles (UAVs) for inspection and surveying, these technologies can enhance productivity and precision while reducing human labor. AI algorithms can guide robots to perform complex tasks, ensuring consistent quality and reducing production time.

Supply Chain Management

Furthermore, AI and analytics can revolutionize supply chain management in the shipbuilding industry. By analyzing historical data and real-time information from suppliers, AI systems can optimize inventory levels, anticipate demand fluctuations, and identify potential bottlenecks in the supply chain. This enables shipbuilders to streamline procurement processes, reduce costs, and ensure timely delivery of materials and equipment.

Improving Performance Maintenance

In terms of operational efficiency, AI and analytics can improve vessel performance and maintenance. By analyzing sensor data from onboard systems, AI algorithms can monitor the condition of critical components, detect anomalies, and predict failures before they occur. This predictive maintenance approach minimizes downtime, extends the lifespan of equipment, and reduces maintenance costs.

Optimizing Route Planning

Moreover, AI-powered analytics can optimize route planning, taking into account factors such as weather conditions, fuel consumption, and cargo demand. By identifying the most efficient routes and speed profiles, ship operators can reduce fuel consumption and emissions, leading to significant cost savings and environmental benefits.

Enhancing Safety and Security

Additionally, AI and analytics can enhance safety and security in the maritime industry. AI systems can analyze data from multiple sources, including radar, sonar, and satellite imagery, to detect and track potential security threats, such as unauthorized vessels or suspicious activities. By providing real-time alerts and insights, AI can support decision-making and improve situational awareness for maritime security personnel.

In conclusion, artificial intelligence and analytics have the potential to transform the shipbuilding and maritime construction industry. From design and engineering to construction, supply chain management, operational efficiency, and safety, these technologies offer numerous opportunities for growth and innovation. By embracing AI and analytics, shipbuilders can optimize processes, reduce costs, improve vessel performance, and ensure sustainable operations in an increasingly competitive and complex maritime environment.

Here are two real-world examples where shipbuilding and maritime construction businesses have benefited from artificial intelligence (AI) and analytics:

Daewoo Shipbuilding & Marine Engineering (DSME) - Virtual Reality and AI for Design and Construction:

DSME, one of the world's largest shipbuilders, has implemented AI and virtual reality (VR) technologies to enhance the design and construction processes. Using AI algorithms and analytics, DSME developed an automated ship design system that generates optimized ship designs based on performance criteria and construction requirements. This AI-powered system analyzes historical data, operational parameters, and environmental conditions to generate designs that maximize fuel efficiency, reduce emissions, and improve overall performance. By leveraging VR technology, DSME also created immersive virtual environments where engineers and stakeholders can visualize and evaluate ship designs before construction, reducing errors and design iterations. These advancements in AI and VR have significantly improved DSME's design efficiency, accuracy, and overall competitiveness in the shipbuilding industry.

Royal Caribbean Cruises - Predictive Maintenance and Data Analytics:

Royal Caribbean Cruises, a leading global cruise line operator, has implemented AI and data analytics to optimize maintenance and operational efficiency. By collecting and analyzing data from onboard sensors and systems, Royal Caribbean uses predictive analytics to monitor the condition of critical components in real-time. AI algorithms detect anomalies and predict potential failures, allowing the cruise line to schedule proactive maintenance activities and avoid unplanned downtime. This approach has resulted in improved vessel reliability, reduced maintenance costs, and enhanced guest satisfaction. Furthermore, Royal Caribbean utilizes data analytics to optimize fuel consumption and route planning. By analyzing historical and real-time data on weather patterns, vessel performance, and fuel consumption, the company identifies optimal routes and speed profiles to minimize fuel usage and reduce emissions, contributing to environmental sustainability.

These examples demonstrate the tangible benefits of AI and analytics in the shipbuilding and maritime construction industry. By leveraging these technologies, companies can optimize designs, streamline construction processes, improve operational efficiency, enhance safety, and reduce costs, ultimately fostering growth and competitiveness in the market.

Summary : How AI and Analytics are changing Shipbuilding and Maritime Construction

If you're interested in learning more about how analytics can help enhance efficiency of your shipbuilding and maritime construction business or learn more about how AI and Analytics are changing shipbuilding and maritime construction industry, we encourage you to contact us today. Our team of experts is dedicated to helping companies like yours optimize their operations through advanced analytics techniques. Whether you're looking to optimize designs, streamline construction processes, improve operational efficiency, enhance safety, and reduce costs , we can work with you to develop a customized solution that meets your specific needs. So don't hesitate – reach out to us today to see how we can help you overcome your business challenges and achieve your business goals.

Comments